How Plastic Injection Molding Guarantees Consistency and Accuracy in Manufacturing

Trick Advantages of Utilizing Plastic Shot Molding in Production

Plastic shot molding has actually become a pivotal strategy in the manufacturing market, offering a series of advantages that dramatically enhance manufacturing procedures. Noteworthy advantages consist of remarkable production performance, the ability for detailed designs, and a positive price structure that attract businesses of all sizes. Furthermore, the versatility of materials made use of in this technique contributes to the durability and reliability of the end products. Understanding these crucial advantages can illuminate how business can enhance their manufacturing methods, but the effects prolong much past preliminary expense financial savings and performance metrics.

High Manufacturing Efficiency

Among the most considerable advantages of plastic injection molding is its high production effectiveness, which can lead to the rapid production of thousands of similar components within a brief duration. This performance is mostly credited to the automatic nature of the injection molding procedure. Once the first setup and mold and mildew creation are completed, the production of parts can be scaled up substantially without an equivalent increase in labor costs or time.

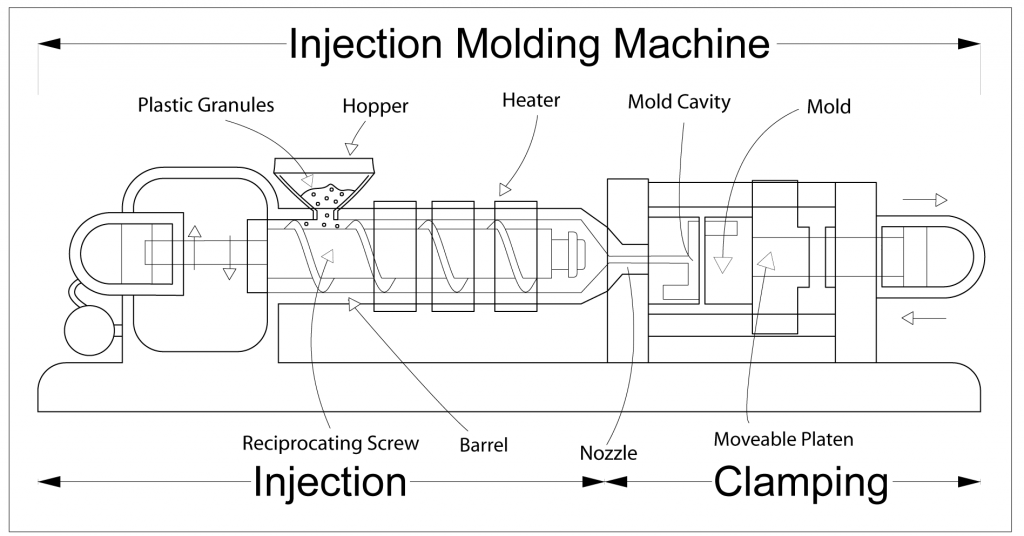

The process usually includes home heating plastic pellets up until they thaw, injecting the molten material right into a precisely developed mold and mildew, and permitting it to cool and solidify - Plastic Injection Molding. This cycle can be completed in mere secs to minutes, relying on the complexity and size of the component being created. As a result, manufacturers can accomplish high output rates, making plastic shot molding an optimal option for automation

Moreover, the ability to generate huge amounts consistently makes sure lower device prices, making it a cost-efficient remedy for companies. This production efficiency not only fulfills market needs swiftly yet also improves the general competitiveness of suppliers in different sectors. Plastic injection molding stays a recommended approach for high-volume production applications.

Layout Adaptability

The capacities of plastic shot molding prolong beyond high manufacturing efficiency to incorporate substantial layout versatility. This production procedure enables engineers and designers to create complicated and intricate shapes that may be challenging or difficult to attain with other techniques (Plastic Injection Molding). The capability to easily adjust and modify mold and mildew designs means that makers can swiftly respond to changing market needs and introduce new product designs without comprehensive retooling

Moreover, plastic shot molding supports a vast array of products, including different thermoplastics and thermosetting polymers. This selection allows the production of components with special residential or commercial properties, such as enhanced stamina, light-weight attributes, or certain thermal and electric attributes. In addition, the process permits for the assimilation of numerous attributes into a solitary part, decreasing the demand for assembly and reducing possible points of failing.

The precision of shot molding additionally guarantees that parts are created with tight resistances, enhancing fit and feature. The flexibility to generate tiny to huge batches effectively further underscores its adaptability, making it an optimal option for both prototyping and large-scale manufacturing. Overall, layout flexibility is a cornerstone advantage of plastic injection molding, driving innovation in many industries.

Cost-Effectiveness

Cost-effectiveness stands out as a considerable benefit of plastic injection molding in production. This procedure permits the mass production of high-quality plastic components at a fairly inexpensive each, specifically when compared to various other manufacturing approaches. The performance of shot molding exists in its capability to generate complicated shapes with minimal waste, enhancing product usage and decreasing general expenses.

Additionally, the rate of manufacturing is an essential aspect in cost-effectiveness. When the first mold is created, the time called for to create each subsequent part is substantially lowered, resulting in raised result and faster turn-around times. This rapid manufacturing capacity not only meets high-volume demands but likewise lessens labor prices, as automated systems can take care of a lot of the procedure.

Moreover, the sturdiness and longevity of injection-molded items add to their cost-effectiveness gradually. These elements commonly require less upkeep and replacement, causing lower lifecycle prices for producers and end-users alike. In recap, the cost-effectiveness of plastic shot molding makes it an eye-catching alternative for businesses looking for to boost their production effectiveness while preserving item high quality.

Material Adaptability

Product flexibility is a characteristic of plastic shot molding, allowing manufacturers to choose from a large range of polymers that meet specific efficiency demands. This flexibility enables the manufacturing of components tailored to numerous applications, ranging from auto parts to customer items.

Typically made use of materials include acrylonitrile butadiene styrene (ABS), polycarbonate (COMPUTER), and polypropylene (PP), each offering special residential or commercial properties such as impact resistance, heat tolerance, and chemical stability. Suppliers can pick materials based upon characteristics like stamina, weight, and thermal security, ensuring completion item satisfies aesthetic and functional requirements.

In addition, the capability to incorporate different polymers with co-injection methods further enhances material convenience. This permits the production of multi-layered elements with distinctive qualities, such as soft-touch surface areas integrated with stiff architectural components.

In addition, improvements in naturally degradable and recycled products are expanding the alternatives available, aligning with sustainability objectives in production. On the whole, the diverse material selections in plastic injection molding equip manufacturers to innovate and enhance their items, promoting the advancement of extremely specialized and competitively advantageous options.

Enhanced Item Resilience

Boosted product durability is just one of the significant benefits supplied by plastic shot molding, as the production process enables precise control over product homes and element design. This precision makes sure that the end products display enhanced mechanical toughness and resilience, which are vital consider a series of applications, from durable goods to industrial components.

Furthermore, the detailed geometries attainable with shot molding allow the creation of components that can withstand stress and stress far better than conventional production methods. The uniform wall surface thickness and minimized discover this info here material waste additionally add to the overall honesty of the product, reducing the opportunities of failure throughout its lifecycle.

Final Thought

To conclude, plastic injection molding offers substantial benefits in production, consisting of high production efficiency, design versatility, and cost-effectiveness. The approach's capability to rapidly generate large amounts of the same components while decreasing labor and material waste is vital. The flexibility in material selection adds to improved product resilience and lower lifecycle prices. These variables collectively establish plastic injection molding as an optimal remedy for automation applications, dealing with the vibrant needs of modern-day manufacturing atmospheres.

Plastic injection molding has actually emerged as a critical method in the manufacturing sector, offering a variety of benefits that significantly improve manufacturing processes.One of the most substantial advantages of plastic shot molding is its high production efficiency, click for more which can result in the rapid production of thousands of identical parts within a short timeframe. Plastic Injection Molding.The capacities of plastic injection molding expand beyond high production performance to encompass substantial layout adaptability.In verdict, plastic injection molding presents considerable benefits this contact form in production, consisting of high production effectiveness, layout adaptability, and cost-effectiveness. These elements collectively develop plastic injection molding as an ideal remedy for mass production applications, attending to the dynamic requirements of contemporary manufacturing atmospheres